Our Technology

- Home

- /

- Our Technology

Prevascularised Bone Implants: Bringing Life to 3D Printed Bone

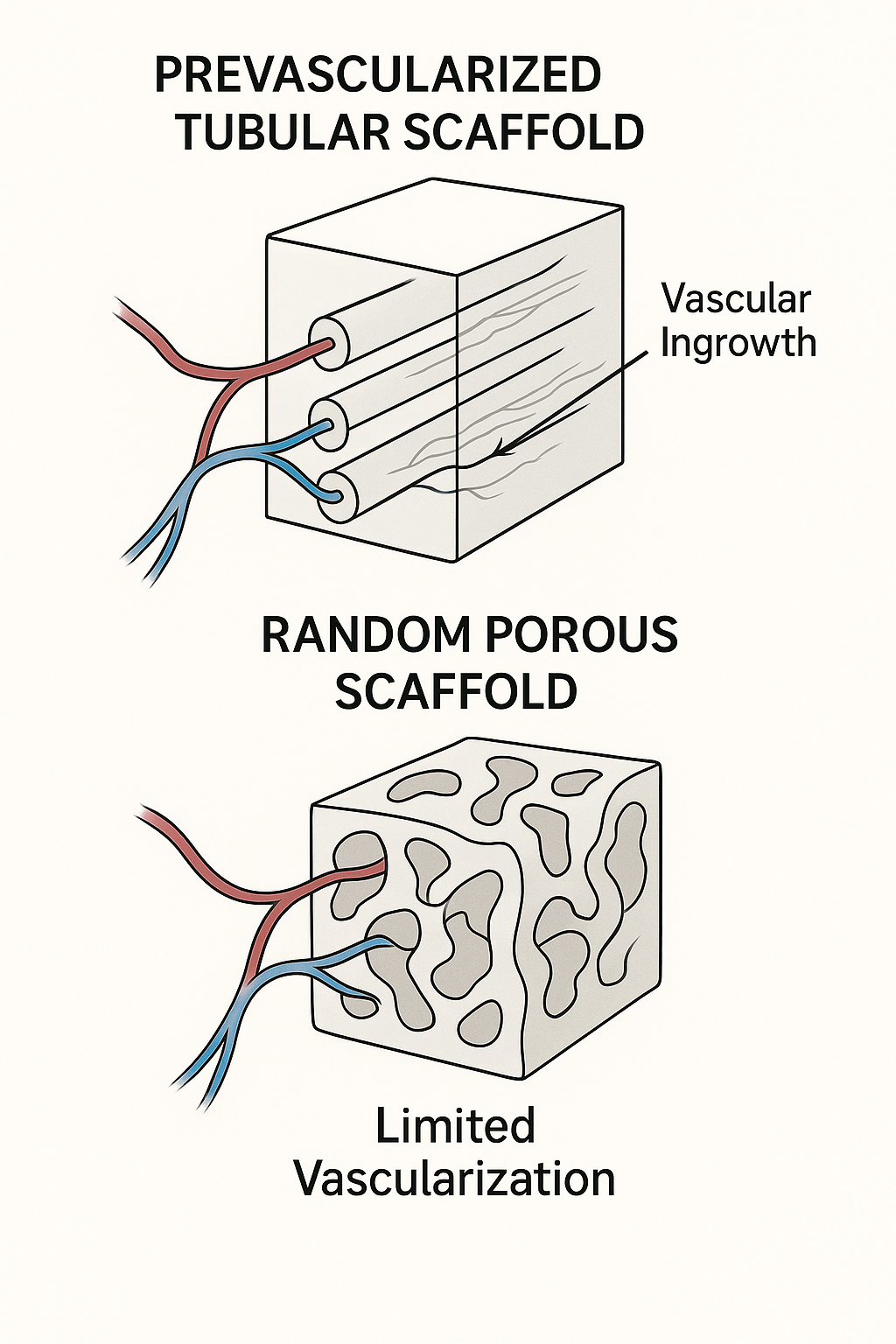

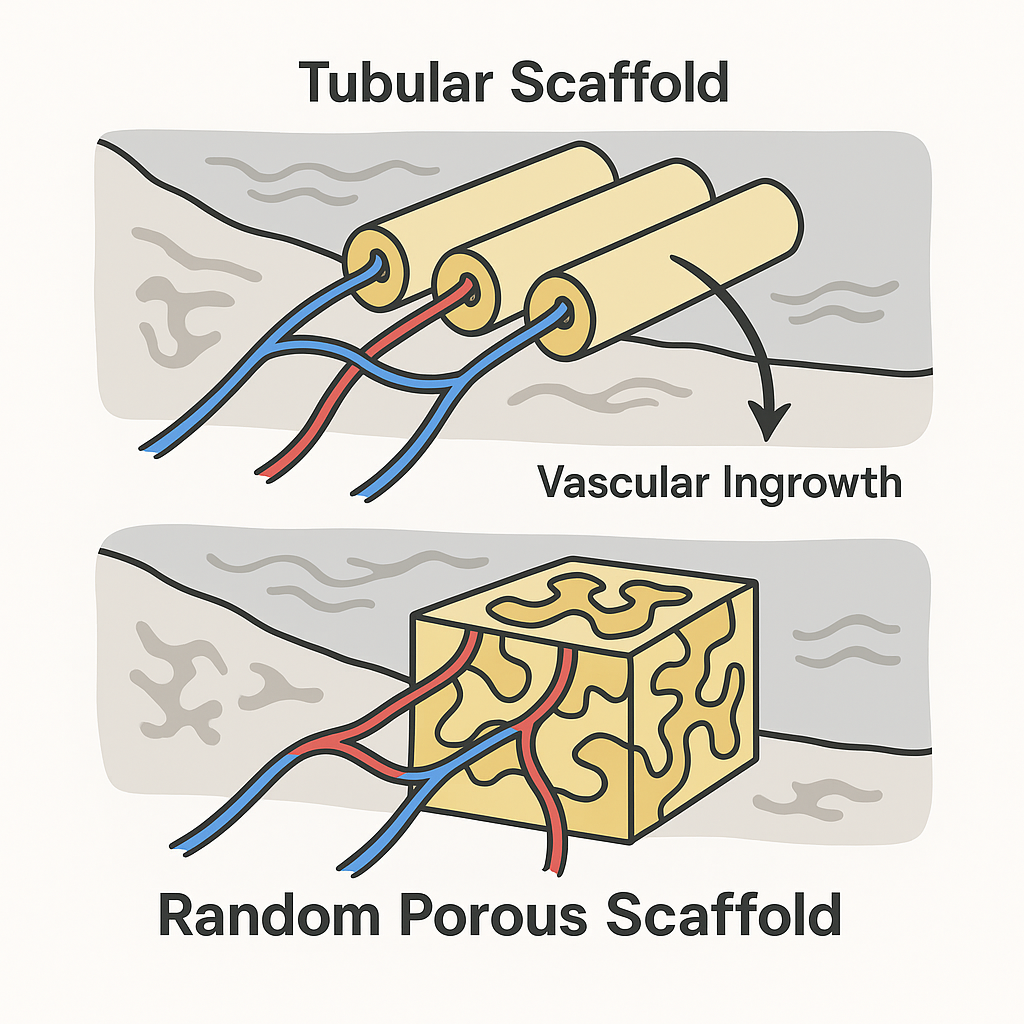

One of the biggest challenges in bone tissue engineering is blood supply. For any implant to survive and integrate, it needs oxygen and nutrients. In natural bone, this comes from an intricate network of blood vessels. Without it, even the most precisely engineered graft will struggle to heal.

This is where prevascularised bone implants come in.

Instead of placing a simple scaffold or block of material into the body, researchers design bone grafts that already contain microvascular channels. These channels act as “pre-formed highways” for blood flow. Once implanted, they connect more quickly to the patient’s own circulation, supporting faster healing and reducing the risk of implant failure.

The promise of prevascularised implants is enormous:

Better survival of engineered bone grafts

Faster regeneration and integration with host tissue

Scalable solutions for repairing large or complex defects

By combining 3D printing with tissue engineering and vascular biology, prevascularised bone implants bring us a step closer to truly living, functional replacements — not just structures that look like bone, but implants that act like bone.

🦴 3D Printing Bone: Breakthrough or Biological Barrier?

3D printing has already reshaped healthcare. From patient-specific implants to surgical guides and experimental tissues, the technology is pushing boundaries once thought impossible.

So the next big question is: can we 3D print bone?

At first glance, the vision is straightforward: design a scaffold that fits a defect, print it, implant it, and let nature do the rest. But bone is not just a structure you can copy — it’s a living system.

Natural bone constantly adapts and renews itself. It contains:

Microscopic channels that carry blood and nutrients

A balance of dense (cortical) and spongy (trabecular) regions

Mechanical properties that shift gradually across the tissue

This complexity makes bone far more than a solid block of material.

3D printing can reproduce shape with remarkable precision. But replicating strength, elasticity, and biological responsiveness remains an unsolved challenge.

The real frontier isn’t just printing a bone-like object — it’s creating something that behaves like bone, heals like bone, and ultimately becomes bone.